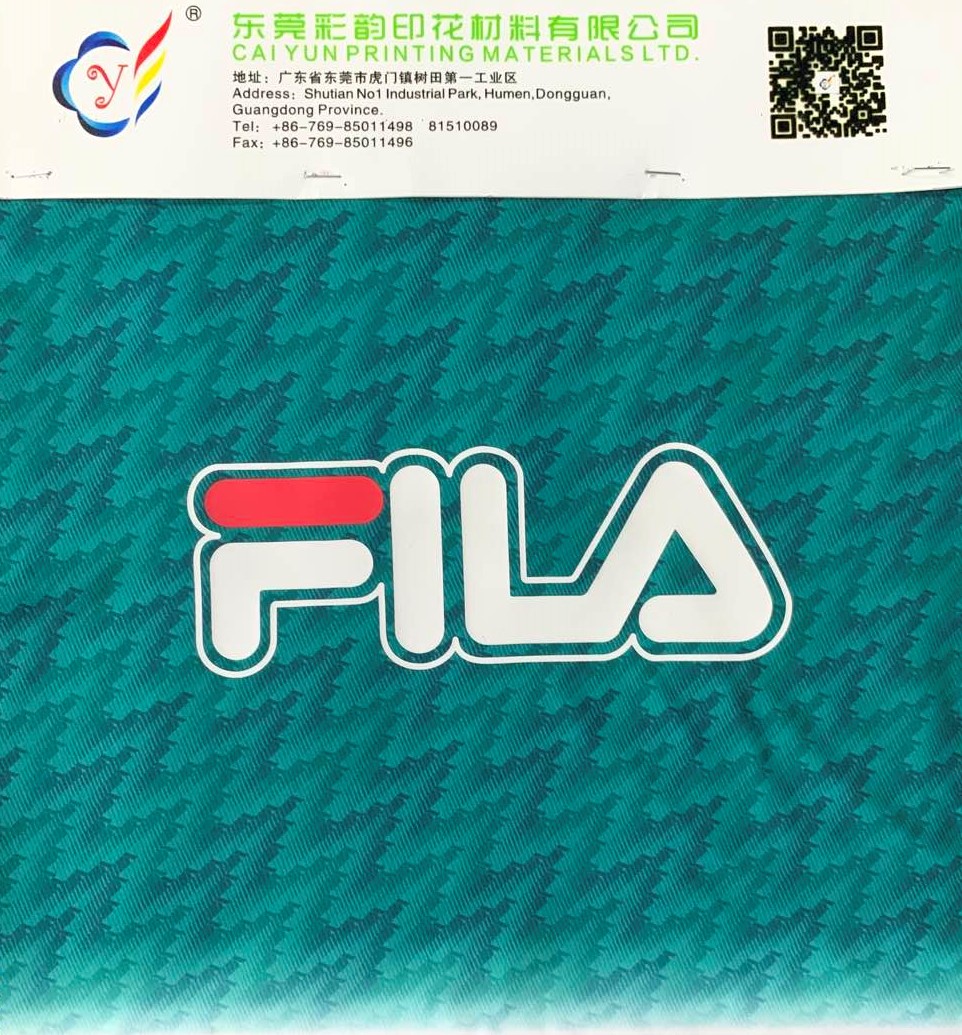

Newly developed High-end Super Soft Machine Print Solution

High-end Super Soft Machine Print Solution

As the fabrics get more and more complicated and customers require higher standard, our company has deleloped a new chemical solution. It has great elasticity, strong fastness and super soft hand feel. It is hazards-free and fully complied, so you can use this solution for high-end brands.

3537D | Soft Clear Underbase Ink |

FE-10 | Anti-migration Ink |

1901T/W | Super Soft Machine Print Ink (Clear/White) |

8918 | PU Matt Coating Ink |

CX200 | Efficient Crosslinker |

SUITABLE

For various fabrics eg cotton, polyester, silicone oil coated, thin and silky, strong migrated fabric.

REQUIREMENTS MET

1. Super soft hand feel

2. Highly elastic and printed ink will return to normal shape after stretching

3. Strong anti-migration performance and super soft hand feel even with anti-migration layers

4. The printed area should not be humped or sunken from the middle.

5. Good white coverage when printing on dark colored fabrics

6. Matt and smooth finishing on top (with top coating)

7. Wet and dry rub test results above 4 (ISO standard)

8. Strong washing durability (60℃ 10-cycle washes*1 hour per cycle, 1200rpm)

9. Not cracking when continuously bending after 48 hours frozen condition at -25℃

10. Eco-friendly, OEKOTEX 100 standard completely complied

11. Not easy to peel off when scratching with fingernails or coins (subjective and destructive test standard)

PRINTING PROCESS

1. Print 3537D +2% CX200 (1 or 2 times) as underbase paste

2. Print FE-10 anti-migration + 0.5% CX200 (optional)

3. Print 1901 white and clear to get the design

4. Print 8918 + 1% CX200 as top coating (1 time)

5. Belt curing at 120-130℃ for 1.5 min after printing